A recent post of mine published on Hackaday talks about the HomeRacker project, a framework for designing and printing to rack-mount anything you’d like.

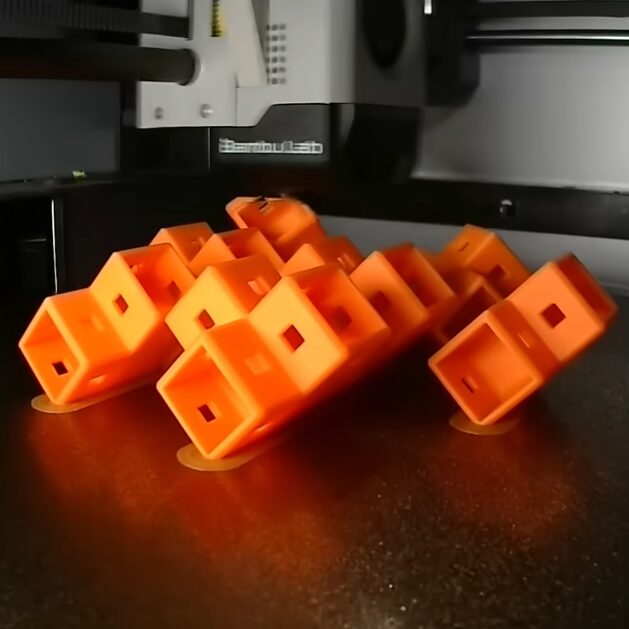

I’d like to go into a bit more detail for one aspect I couldn’t really cram into the original post: the way HomeRacker parts are designed for 3D printing, and particularly the way they are printed at an angle, like what you see below (a screenshot from the HomeRacker project video.)

There are several advantages to printing in this way.

Most people print a box shape flat on the bed. But there are a number of advantages to printing like what you see here:

- No need for supports. Printing at a 45 degree angle is something just about any printer can handle. It’s a modest degree of overhang. As you can see, no supports are needed.

- No supports means a smaller footprint and less material. This also means more parts fit on the bed, and parts print faster. Why faster? Less material is being used, so the printer has less to do. And no supports means there is minimal post-processing for the operator to do.

- It makes a stronger part. Printing at an angle that is not in the same plane as a box-like part generally means a stronger part.

- Printing at an angle has less of a 3D printed “look”. For one thing, the part won’t have the texture of the print bed on one side with layer lines straight up from that. As a result the part will have a more uniform appearance and finish, with the layer lines not being orthogonal to the part’s geometry. (This is even more true if combined with something like ‘fuzzy skin’)

So consider printing your next box-ish shape (like an enclosure) at an angle. You might be surprised at what’s possible.